DURHAM — Blame it on the rain.

After several days of inclement weather — and delays to baseball games — the Durham Bulls’ tarp had finally had enough.

The 15,000-square-foot vinyl sheet that protects the Durham Bulls Athletic Park field from rain had been unrolled and rolled back up multiple times a day for the last week, and a small tear — barely noticeable to anyone — had begun near one edge.

When the tarp was anchored and covering the field, a gust of wind caught a corner, and the 1,000-pound tarp began to flap violently. The grounds crew rushed out and got it under control, but the damage was done. The small tear had become a full-fledged rip, extending some 30 feet — a significant problem for something specifically designed to not leak.

With more rain expected as the North Carolina summer was just getting started, the Bulls’ grounds crew needed to act fast to repair the damage. There was no doubt who the first call would go to — a sweet, outgoing woman named Debbie Bryda, who has served as the Bulls’ team seamstress for more than a decade.

Bryda is well versed in fixing baseball-related rips and tears for the Bulls, but it usually involves cloth, not industrial-strength vinyl. But she showed up with the same Janome sewing machine she uses to mend clothes, ready to take on the tarp.

“They had to roll it out for me,” she explained, sounding a little self-conscious over the number of people that effort entailed. “But yeah … I did what I could.”

What she could do was mend and patch the rip, at least to the extent that it no longer leaked onto the infield it was designed to protect. Bryda wasn’t intimidated by the prospect of mending something so large and heavy. “It’s like working with a queen-sized quilt,” she explained. “You’ve got to flip it over to get at it.” Bryda shrugged, miming as if lifting something heavy and draping it away from her machine. “It’s easier if you have a Longarm (a sewing machine specially designed for quilting),” she continued, “but this works.”

Even when the tarp is intact, the Bulls have enough work to keep Bryda busy throughout the season. She can be found before many home games sitting at a table in the DBAP’s 919 club on the luxury suite level, her Janome on one side of her and a large stack of Bulls jerseys and pants on the other.

Ballplayers are tough on uniforms. Buttons come off jerseys and pants get torn due to a slide into a base or a diving catch in the field. Bryda can get those types of things repaired and patched by the next game. That’s a luxury not many teams at the minor league level enjoy.

“Most teams have to send this stuff out,” she said, referring to sending the uniforms to a local business that does tailoring and alterations. “Some teams will work on the road uniforms while the team is playing at home, and vice versa. So there’s a wait to get things fixed. A lot of times, I’ll get a pair of pants that have a rip, and I’ll ask the player, ‘Do you need these today?’ They’re shocked (it can be done that fast.)”

“Most teams have to send this stuff out,” she said, referring to sending the uniforms to a local business that does tailoring and alterations. “Some teams will work on the road uniforms while the team is playing at home, and vice versa. So there’s a wait to get things fixed. A lot of times, I’ll get a pair of pants that have a rip, and I’ll ask the player, ‘Do you need these today?’ They’re shocked (it can be done that fast.)”

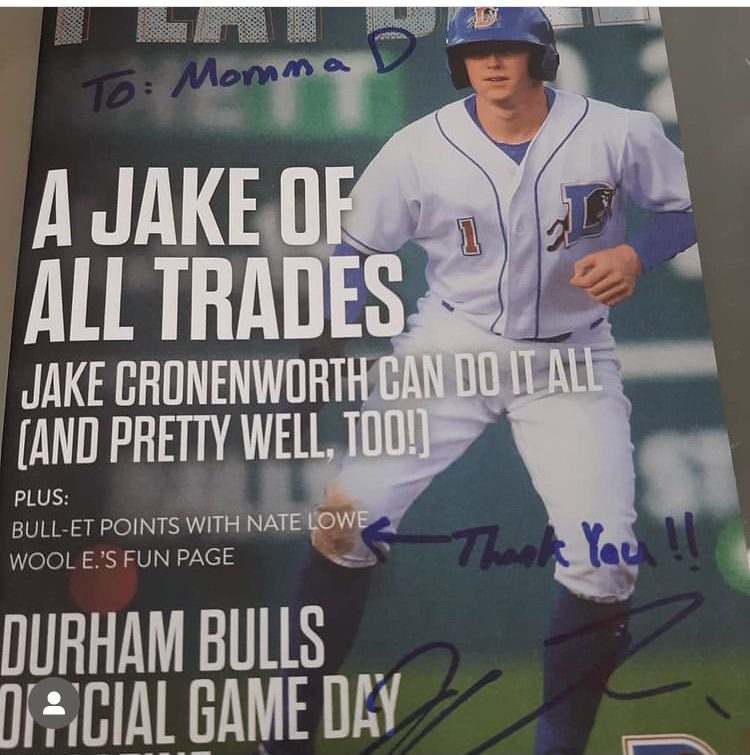

Current San Diego Padres infielder Jake Cronenworth signed a Bulls program for her, drawing an arrow to the clearly patched knee of his uniform pants in the cover photo and writing “Momma, Thank you!!!”

As the season hits July, Bryda has to gear up for her busy time. The trade deadline is the equivalent of tax season for a team seamstress. Minor leaguers are the currency as MLB teams add star players for the stretch run, and that means a lot of last-minute roster changes. And when those new players arrive in Durham, they’re going to need Bulls jerseys — that fit — with their names on the back. Bryda handles all of that. She sews the nameplates and attaches them. And she makes sure everything fits just right so a batter’s swing or pitcher’s windup isn’t hampered by something tight in the wrong spot.

She also handles alterations that have a … less functional reason. There are some players who just like to look good while out on the field, and they’ll come to Bryda with alteration requests that will help make sure they cut the right silhouette out there.

Then there’s the mascot. Wool E. Bull is the large-headed, fuzzy face of the team for the fans. And whether he needs a flight suit for Top Gun night or a mask that fits across his oversized mouth, it’s tough to buy off the rack for him. So Bryda is sometimes called into service to design him something. She proudly points out Wool E.’s COVID mask is her handiwork.

Jerry Seinfeld famously joked that with players changing teams so frequently, we’re now just “rooting for laundry.” Debbie Bryda makes sure that, at least for the players that come and go so quickly on the Durham Bulls, the laundry is ready to go when it’s needed.

And, if the rain doesn’t stop, she can help with that, too.